If you run a retail or logistics business, inventory control is a necessary evil that you must put up with every once in a while. Not only does it require hours, you may need to temporarily shut down your store in order to do it. While you may not be able to reduce the tedium, the following tips will ensure that you get it done right, and fast.

Plan in advance

Since inventory counting takes time, it is important that you plan for it in advance. Because it may require that you close your store, you need to determine the best time of the day or week when shutting down will not terribly affect your sales. It is a good idea to schedule your inventory counting for after office hours, possible for over the night so that you can do it with fewer distractions.

Make a map of your facility

Having a visual map of your store or facility will make the counting process seem less daunting for you and your staff. A map of your facility shows you specific areas that need attention and it makes it easy for you to assign people to those areas to make the counting process seamless and fast. A visual map will also serve as a useful checklist when you are actually doing the counting as you can mark off areas you have covered, making it easier to see how much you have done and what is left.

Organize beforehand

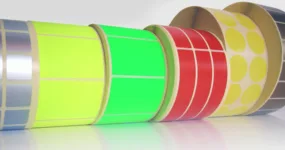

It would not do to start your inventory only to realize that some items are not where they ought to be. Arrange the items in their positions so that they can easily be counted. Don’t just rush into the task blindly, be sure to mark those products or boxes clearly to indicate if they would be counted or not. Each item should have an SKU or a barcode number. Additionally you will need some coloured stickers or labels to place identify areas that have been counted so as not to do a repeat, which will give you a wrong figure. You can easily get coloured sticky labels inexpensively online.

Identify inventory that should not be counted

If possible, inventory items such as returns and receipts should be dealt with before the count begins. The same thing applies to damaged products. Any faulty products discovered before the inventory should be handled early on. In the event that you receive merchandise during the counting process, set them aside for later so as not to muddle up everything.

Organize your team

If you plan to do a full inventory that would include your staff, then you need to give them adequate heads up. This will help them plan their schedule, especially if the inventory count will happen at night. Physical inventory should be handled by no more than 2 persons, one to do the actual counting and the other to record the data. There is less possibility of error this way. Don’t forget to have a supervisor who will monitor the counts in each section of your facility for accuracy.

Add a slice of fun

Okay, so inventory counting is tedious and boring, you can actually do your bit to make it less so. Put your favourite playlist on low volume and give the atmosphere a bit of festive spirit during the counting process. Don’t forget to plan for light refreshments for your team. After all, muzzle not the ox and all of that.